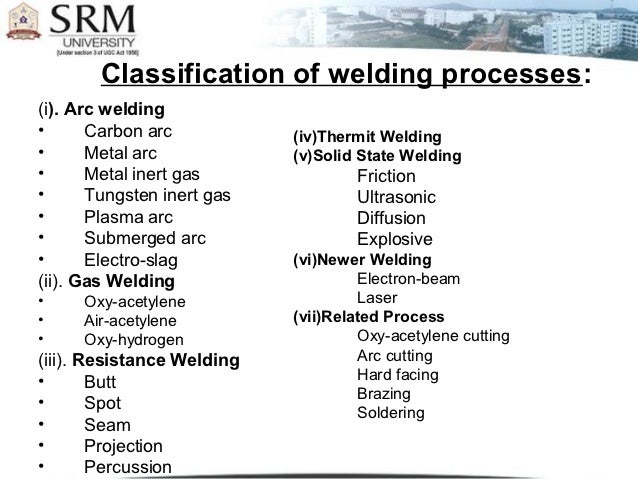

WELDING AND ALLIED PROCESSES 1. SCOPE 1.1 Intent. This standard specification and appendices describe the general requirements for welding, fabrication, brazing, inspection, and associated processes on Coast Guard vessels and equipment. 1.2 Appendices. PROCESS STANDARD APPENDIX Commercial Welding Standards A. Of the welding processes listed in figure 3-1, shielded metal arc welding, called stick welding, is the most common welding process. The primary differ-ences between the various welding processes. Processes − tungsten plasma arc welding (PAW) − inert-gas tungsten-arc welding (TIG), whereby TIG welding is the most widely used fusion welding process for aluminium. The plasma welding consists only of the plasma-arc welding process which works with a transferred arc. Welding and Metal Fabrication Book pdf by by Larry Jeffus. Welding and Metal Fabrication is designed to help you develop all of the skills to become a highly paid versatile welder. In addition, it is designed to make the process of learning to weld interesting and rewarding by having everything you weld on become something you can. This is a list of welding processes, separated into their respective categories.The associated N reference numbers (second column) are specified in ISO 4063 (in the European Union published as EN ISO 4063).

This is a list of welding processesC by robert lafore pdf. , separated into their respective categories. The associated N reference numbers (second column) are specified in ISO 4063 (in the European Union published as EN ISO 4063).[1] Numbers in parentheses are obsolete and were removed from the current (1998) version of ISO 4063. The AWS reference codes of the American Welding Society are commonly used in North America.[2]

Arc welding[edit]

| Name | N | AWS | Characteristics | Applications |

|---|---|---|---|---|

| Bare Metal Arc Welding | (113) | BMAW | Consumable electrode, no flux or shielding gas | Historical |

| Carbon Arc Welding | (181) | CAW | Carbon electrode, historical | Copper, repair (limited) |

| Flux Cored Arc Welding | 136 137 | FCAW FCAW-S | Continuous consumable electrode filled with flux | Industry, construction |

| Gas Metal Arc Welding[3] | 131 135 | GMAW | Continuous consumable electrode and shielding gas | Industry |

| Gas Tungsten Arc Welding[4] | 141 | GTAW | Nonconsumable electrode, slow, high quality welds | Aerospace, Construction (piping), Tool and Die |

| Plasma Arc Welding | 15 | PAW | Nonconsumable electrode, constricted arc | Tubing, instrumentation |

| Shielded Metal Arc Welding[5] | 111 | SMAW | Consumable electrode covered in flux, can weld any metal as long as they have the right electrode | Construction, outdoors, maintenance |

| Submerged Arc Welding | 121 | SAW | Automatic, arc submerged in granular flux | |

| Magnetically Impelled Arc Butt | 185 | MIAB | both tube ends are electrodes; no protection gas; arc rotates fast along edge by applied magnetic field | pipelines and tubes |

| Atomic Hydrogen Welding | (149) | AHW | Two metal electrodes in hydrogen atmosphere | Historical |

Stick welding is the most basic and common type of welding processes used. It is also the first process learned in any welding school. Stick is the most trouble free of all of the welding processes and is the fundamental basis for all the skills needed to learn how to weld! Stick welders have four main components: A ground lead or clamp. . Solid-state Welding Processes – Forge welding – Samurai sword – Cold welding – high pressure – Roll welding – Hot-pressure welding – Diffusion welding at 0.5T m – Explosive welding – mechanical locking commonly used to bond two dissimilar metals, in particular to clad one metal on top of a base metal over large areas.

Oxyfuel gas welding[edit]

| Name | N | AWS | Characteristics | Applications |

|---|---|---|---|---|

| Air acetylene welding | (321) | AAW | Chemical welding process, not popular | Limited |

| Oxyacetylene welding | 311 | OAW | Combustion of acetylene with oxygen produces high-temperature flame, inexpensive equipment | Maintenance, repair |

| Oxygen/Propane welding | 312 | Gas welding with oxygen/propane flame | ||

| Oxyhydrogen welding | 313 | OHW | Combustion of hydrogen with oxygen produces flame | Limited |

| Pressure gas welding | PGW | Gas flames heat surfaces and pressure produces the weld | Pipe, railroad rails (limited) |

Resistance welding[edit]

| Name | N | AWS | Characteristics | Applications |

|---|---|---|---|---|

| Resistance spot welding | 21 | RSW | Two pointed electrodes apply pressure and current to two or more thin workpieces | Automobile industry, Aerospace industry |

| Resistance seam welding[6] | 22 | RSEW | Two wheel-shaped electrodes roll along workpieces, applying pressure and current | Aerospace industry, steel drums, tubing |

| Projection welding | 23 | PW | Semi-Automatic, Automatic, Welds are localized at predetermined points. | |

| Flash welding | 24 | FW | ||

| Upset welding | 25 | UW | Butt joint surfaces heated and brought together by force |

Mig Welding Process Pdf

Solid-state welding[edit]

| Name | N | AWS | Characteristics | Applications |

|---|---|---|---|---|

| Coextrusion Welding | CEW | Dissimilar metals are extruded through the same die | Joining of corrosion resistant alloys to cheaper alloys or alloys with more favorable mechanical properties | |

| Cold pressure welding | 48 | CW | Joining of soft alloys such as copper and aluminium below their melting point | Electrical contacts |

| Diffusion welding | 45 | DFW | No weld line visible | Titanium pump impellor wheels |

| Explosion welding | 441 | EXW | Joining of dissimilar materials, e.g. corrosion resistant alloys to structural steels | Transition joints for chemical industry and shipbuilding. Bimetal pipelines |

| Electromagnetic pulse welding | Tubes or sheets are accelerated by electromagnetic forces. Oxides are expelled during impact | Automotive industry, pressure vessels, dissimilar material joints | ||

| Forge welding | (43) | FOW | The oldest welding process in the world. Oxides must be removed by flux or flames. | Damascus steel |

| Friction welding | 42 | FRW | Thin heat affected zone, oxides disrupted by friction, needs sufficient pressure | Aerospace industry, railway, land transport |

| Friction stir welding | FSW | A rotating non-consumable tool is traversed along the joint line | Shipbuilding, aerospace, railway rolling stock, automotive industry | |

| Hot pressure welding | HPW | Metals are pressed together at elevated temperatures below the melting point in vacuum or an inert gas atmosphere | Aerospace components | |

| Hot isostatic pressure welding | 47 | HPW | A hot inert gas applies the pressure inside a pressure vessel, i.e. an autoclave | Aerospace components |

| Roll welding | ROW | Bimetallic materials are joined by forcing them between two rotating wheels | Dissimilar materials | |

| Ultrasonic welding | 41 | USW | High-frequency vibratory energy is applied to foils, thin metal sheets or plastics. | Solar industries-. Electronics. Rear lights of cars. Diapers. |

Arc Welding Process Pdf

Other types of welding[edit]

| Name | N | AWS | Characteristics | Applications |

|---|---|---|---|---|

| Electron beam welding | 51 511 | EBW | Deep penetration, fast, high equipment cost | |

| Electroslag welding | 72 | ESW | Welds thick workpieces quickly, vertical position, steel only, continuous consumable electrode. | Heavy plate fabrication, construction, shipbuilding. |

| Flow welding | Distortion is minimized, and the thermal cycle is relatively benign [7]. | Joining rails in situ (in the form of thermit welding) | ||

| Induction welding | 74 | IW | ||

| Laser beam welding | 521 522 | LBW | Deep penetration, fast, high equipment cost | Automotive industry |

| Laser-hybrid welding | Combines LBW with GMAW in the same welding head, able to bridge gaps up to 2mm (between plates), previously not possible with LBW alone. | Automotive, Shipbuilding, Steelwork industries | ||

| Percussion welding | 77 | PEW | Following an electrical discharge, pressure is applied which forges the materials together | Components of switch gear devices |

| Thermite welding | 71 | TW | Exothermic reaction between alumnium powder and iron oxide powder | Railway tracks |

| Electrogas welding | 73 | Continuous consumable electrode, vertical positioning, steel only | Storage tanks, shipbuilding | |

| Stud arc welding | 78 | Welds studs to base material with heat and pressure |

Notes and references[edit]

- ^ISO 4063: 'Welding and allied processes - Nomenclature of processes and reference numbers' (1998)

- ^'Welding Inspection Handbook', 3rd edition, American Welding Society, ISBN0-87171-560-0, Miami, FL, pp. 10-11 (2000)

- ^Also known as metal inert gas (MIG) welding or metal active gas (MAG) welding.

- ^Also known as tungsten inert gas (TIG) welding.

- ^Also known as manual metal arc (MMA) welding or stick welding.

- ^Also known as electric resistance welding (ERW).

- ^'جوشکاری گدازی FLOW Welding شریف +'. www.sharifplus.ir (in Persian). Retrieved 2018-09-28.

- Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. ISBN0-13-113029-3.

- Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland: Lincoln Electric. ISBN99949-25-82-2.